As we officially launch the Lifeboat Tire Lever, we thought we'd give you some insight on how the product is made, the faces, and the process behind it. We like knowing the people who make our products, and thought you would too.

IT STARTED AS AN IDEA

A TIRE LEVER FOR MODERN TUBELESS TIRE MAINTENANCE

Today's modern bikes have tubeless wheels, and tire levers aren't built for tubeless tires. The Lifeboat Tire Lever solves this problem and does even more.

The idea happened when Snek founder Jonny Hintze was doing a repair to his tubeless wheels and found himself searching for his small missing valve core removal tool, needle nose pliers, or anything that would allow him to remove the valve core so he could add sealant. That's when it dawned on him. Why not just have a valve core remover as part of the tire lever? That way the tool is always there when a tubeless tire needs to be serviced. Whether installing new tires, removing old ones, or fixing a flat with either sealant or a tube, the tools are there.

PROTOTYPES WERE MADE

The idea went to the drawing board, then to some physical 3D printed samples to make sure the idea, design and structure were sound.

While the idea was there, it didn't come together perfectly the first time. Perfection is a process, and as with all Snēk products - they're carefully evaluated and vetted.

PROJECT WAS FUNDED ON KICKSTARTER

To test the waters, the idea was pitched and ultimately funded on Kickstarter. It turns out that other people were struggling with the same issue, and wanted a solution. Thank you supporters for making it happen! Couldn't have done it without you.

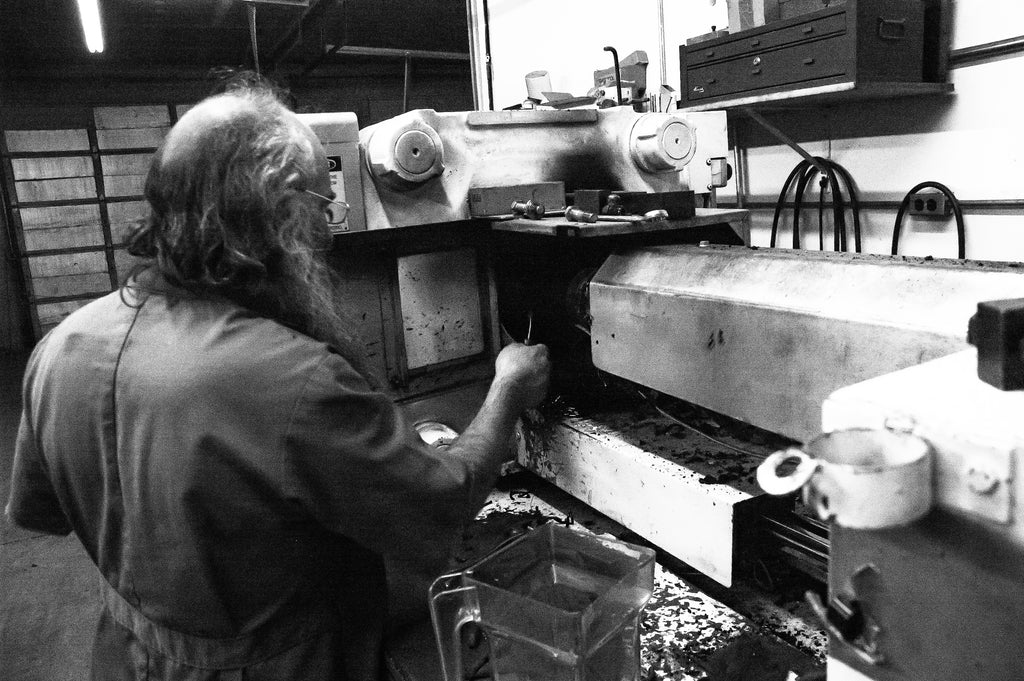

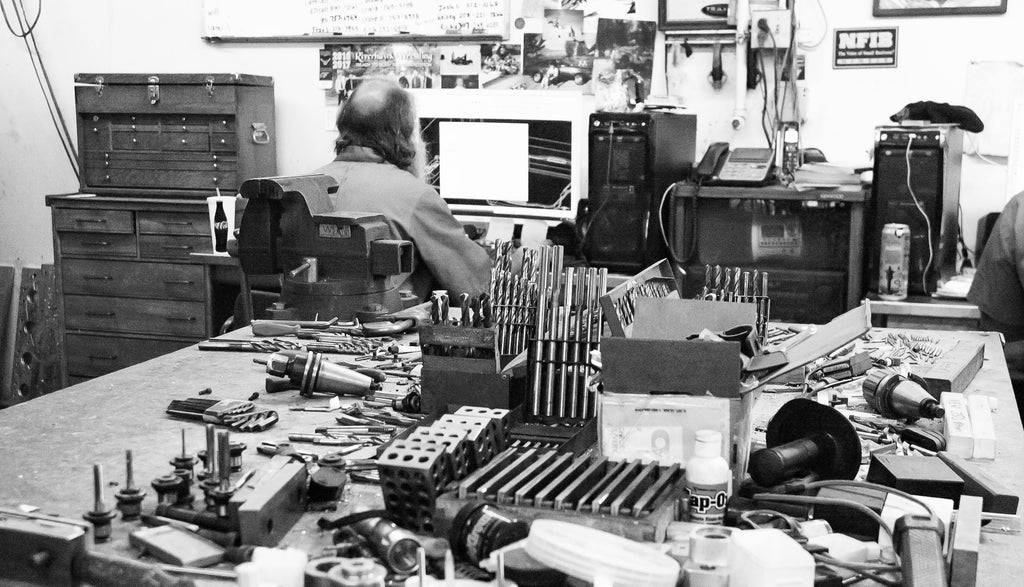

A LOCAL MANUFACTURER WAS FOUND

As with all our products, we start locally to manufacture them, then branch out from there. Luckily, we didn't have to branch out too far till we found Steve, a Utah native with the knowledge and experience to make it happen.

The manufacturing process can be painstaking at times, even frustrating, filled with revisions, and numerous prototypes, which not every manufacturer is up for. Some settle at "good enough" but for us, "good enough" is not enough.

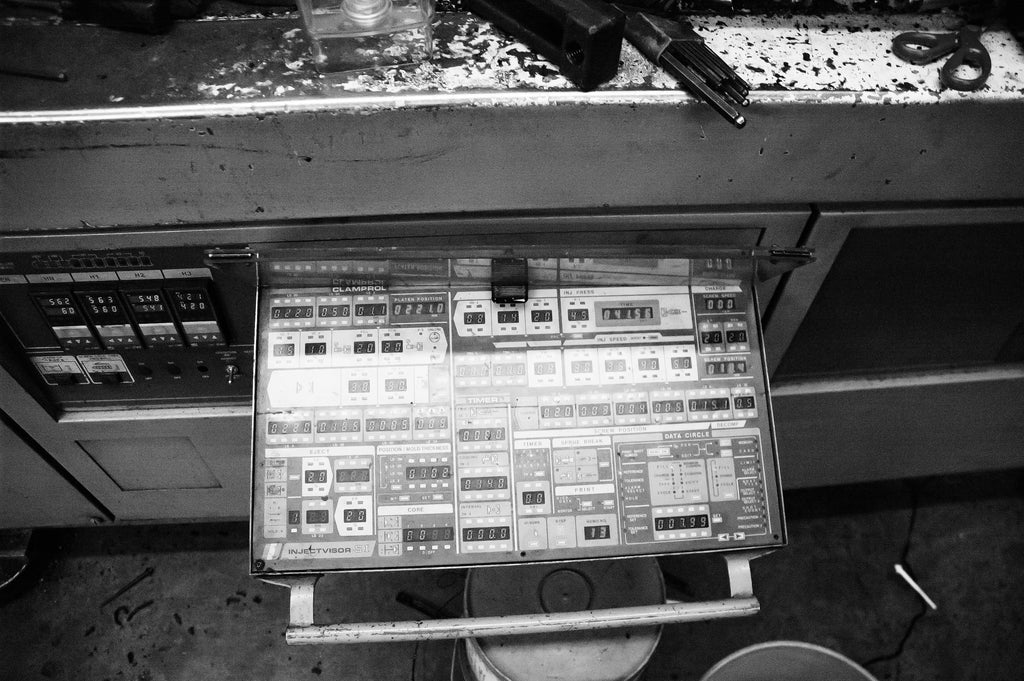

TOOLING WAS CUT

Our Lifeboat Tire Levers are constructed with a metal core for added strength, and a plastic outer to protect the rim. In order to make the product, some tooling was required to shape and house both the plastic and metal. Since our levers have a metal insert, with valve core removers, additional features were required to locate and suspend the metal insert inside the mold.

Once the mold was cut, the parts were ready for testing.

To make the levers, metal inserts are manually placed inside each mold, sandwiched between the top and bottom, then pressurized for injection molding. The product is then formed and cured.

FIRST PARTS MADE

Various plastic compounds were tested at different temperatures and compositions. The plastic and mold were modified as needed based on results. Many hours were spent finding the right recipe to create a part that met our standards.

TESTING

After checking and testing the quality, function and strength of the levers, both in the shop and on the trail, they were ready for production.

READY FOR THE WILD

Finished product was then delivered to our Kickstarter backers and is now available online and in shops worldwide.

MADE IN USA. BUILT TO LAST. GUARANTEED FOR LIFE.

“I needed a reliable tire lever, just as much as I needed a reliable valve core remover. The small, plastic core removers become lost too easily, and levers broke all too often. Having both on the same tool, I realized, would save me a lot of effort. It wasn't perfect, at first - but I learned from each iteration. It became simpler with each revision. It's a tool that will never leave my side” – Jonny Hintze, founder of Snēk.

Altogether, the Lifeboat Tire Lever is designed to help make the lives of cyclists slightly easier. Think less about your equipment, and more about the ride.